When your project calls for an impermeable geomembrane,HDPE is often the gold standard. But simply ordering an “HDPE liner” is not enough. As a buyer, you must understand the specifications that dictate quality, longevity, and ultimately, value for money. Here‘s what to discuss with your non woven geotextile suppliers(many of whom also supply geomembranes) or specialized manufacturers.

Key Specification Points for HDPE Geomembrane Sheet

1.Resin Quality:

The heart of the product. Ask for virgin, high-quality resin (not recycled). This ensures consistent chemical resistance and long-term durability. The density should be ≥ 0.940 g/cm³.

2.Thickness & Tolerance:

Thickness (e.g., 1.0mm, 1.5mm, 2.0mm) directly relates to puncture resistance and longevity. Ensure the supplier guarantees a minimum thickness, not just an average. Tolerance should be tight (e.g., ± 5%).

3.Textured vs. Smooth:

Smooth hdpe liner sheet is standard. Textured geomembrane (on one or both sides) provides increased interface friction, crucial for slopes. This prevents the liner from sliding. Specify based on slope design.

4.Carbon Black Content & UV Stabilization:

For exposed applications, the sheet must contain 2-3% carbon black (evenly distributed) and UV stabilizers. This prevents degradation from sunlight. Ask for relevant test reports (e.g., ASTM D7238 for oxidative induction time).

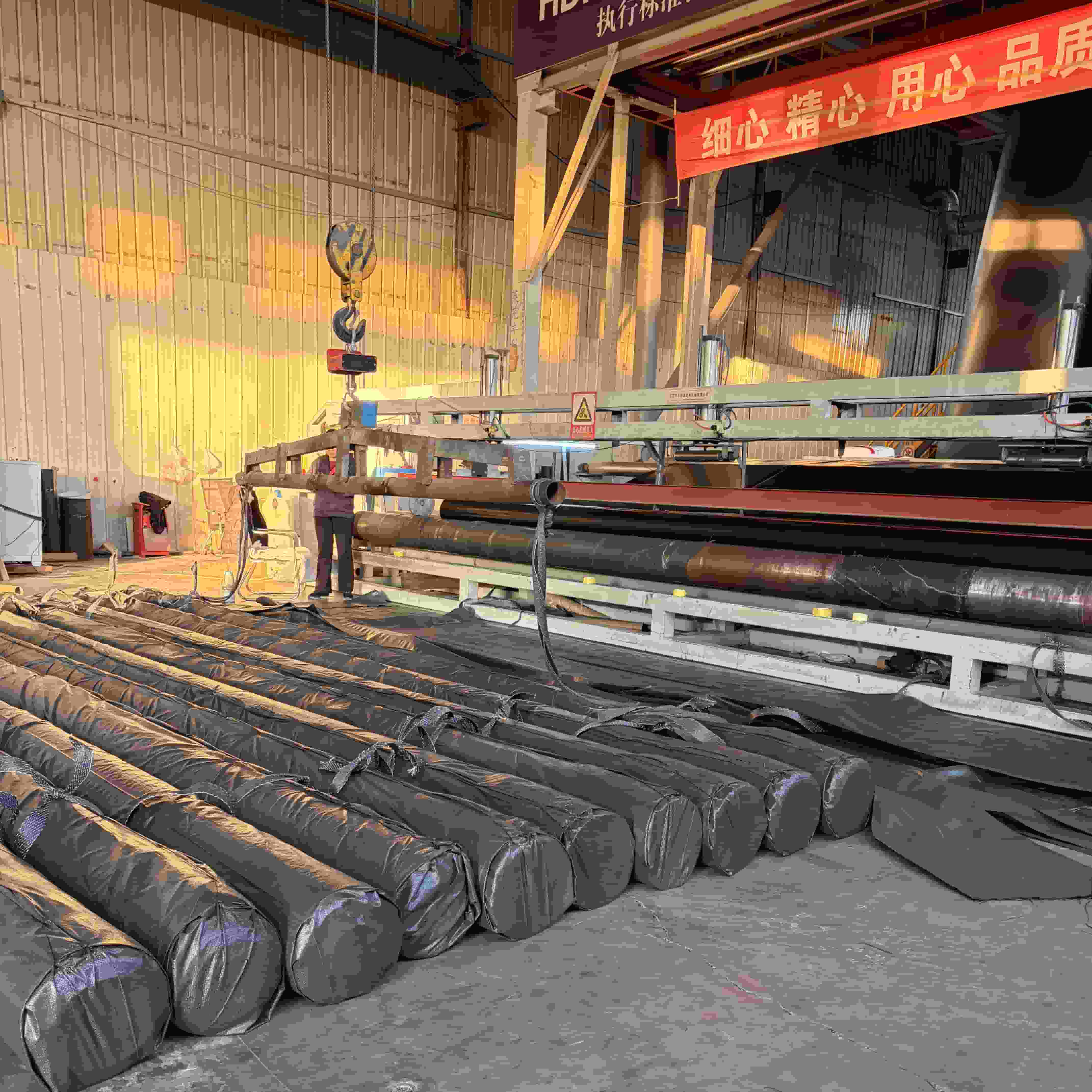

5.Panel Size & Seam Integrity:

Larger factory-fabricated panels mean fewer field seams, reducing potential leak points. For seams, inquire about the welding procedure specification (WPS) and the qualification of welders.

Beyond the Sheet: The System Approach

An hdpe geomembrane sheet is part of a system. It needs protection. This is where non woven geotextile fabric comes in as a critical cushion layer. A reputable supplier will not just sell you the membrane but advise on the complete system, including the appropriate geo fabric material for protection and a potential GCL liner for a composite system.

Procurement Action Plan

- Do notbuy on price alone.

- Dorequest certified test reports for resins and finished sheets.

- Doask for project references and case studies.

- Doconsider the supplier‘s technical support and ability to provide a system solution.

Investing in a properly specified HDPE geomembrane from a quality-conscious manufacturer prevents costly failures and protects your project’s environmental and structural integrity.