What is a sandwich panel?

A sandwich panel is a product used for cladding building walls and roofs. It consists of an insulated core material sandwiched between two metal sheets. A sandwich panel is not a structural material, but rather a cladding material. While the structural forces are carried by a steel frame or other supporting framework, the sandwich panel is attached to it.

Types of sandwich panel

☆Classification by Application

|

|

Wall panels |

Sandwich panels are used for vertical building envelopes, requiring aesthetic appeal and fire resistance.

|

|

|

Roof panels |

Sandwich panels are engineered for horizontal installation, prioritizing waterproofing and load-bearing capacity.

|

☆Classification by Core Material

Sandwich panels' performance is primarily determined by their core material, categorized into four key types:

|

|

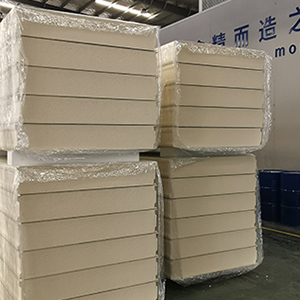

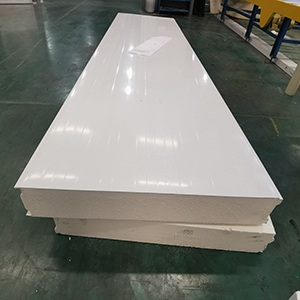

Polyurethane (PU)/Polyisocyanurate (PIR) core sandwich panels |

Featuring ultra-low thermal conductivity (as low as 0.022 W/m·K) and high structural strength, They are extensively used in temperature-controlled environments (e.g., cold storage, cold chain logistics centers).

|

|

|

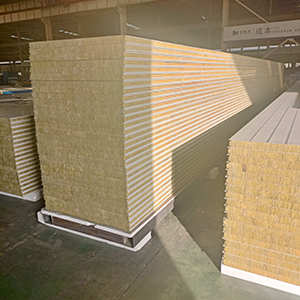

Rock wool core sandwich panels |

With Class A non-combustibility, these panels provide optimal fire resistance for high-safety facilities (e.g., hospitals, chemical plants). But they exhibit strong hygroscopicity, requiring strict seam sealing during installation.

|

|

|

Expanded polystyrene (EPS) core sandwich panels

|

With ≈60% lower cost than rock wool panels and lightweight properties (10–14 kg/m²), But they are flammable and emit toxic fumes, restricting their use to temporary structures or non-fire compartment areas.

|

|

|

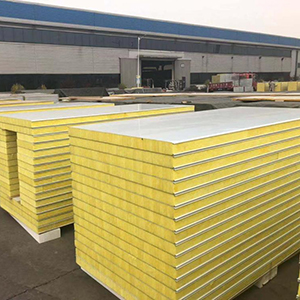

Glass wool core sandwich panels |

As a balanced option, they surpass rock wool in thermal insulation and outperform EPS in fire resistance. Hydrophobic types must be selected to ensure moisture resistance (water absorption ≤2%) |