--Introduction

Standing tall yet deceptively slender, monopole communication towers defy intuition: How can a single steel column support tons of antennas, survive hurricanes, and last decades? The answer lies in meticulous engineering that transforms simplicity into strength. This blog unravels the structural wizardry behind monopole towers—from their hidden geometry to advanced simulations that ensure unshakable stability.

1. The Art of Monopole Mechanics: More Than Just a Steel Tube

- The "Magic" of Tapered Design

- Conical Geometry: Towers taper from base (1–1.5m diameter) to top (0.3–0.5m), optimizing weight distribution and bending resistance.

- Wall Thickness Gradients: Base walls are 2–3x thicker (16–25mm) than upper sections (6–10mm), concentrating strength where stress peaks.

- Sectional Fabrication: Towers are built from 6–12m segments, flanged or slip-fit for precision alignment.

- Key Formula: Bending Resistance

I = \frac{\pi (D_o^4 - D_i^4)}{64}

Where:

-

I = Moment of inertia (resistance to bending)

-

Dₒ = Outer diameter

-

Dᵢ = Inner diameter

Insight: Doubling diameter increases bending resistance 16x!

2. Taming the Wind: Computational Fluid Dynamics (CFD) in Action

Wind Load Simulation Workflow

Wind Mapping:

- China GB Standard: Classifies sites into 6 wind zones (28–55 m/s).

- IEC 61400-6: Uses 4 classes (22.5–52.5 m/s).

CFD Modeling:

- Tools: ANSYS Fluent or OpenFOAM simulate vortex shedding and pressure distribution.

- Critical Output: Drag coefficient (Cd) and lift forces at varying wind angles.

Real-World Calibration:

- Case: A 50m tower in Zhuhai (typhoon zone) withstood 60 m/s winds after CFD-guided reinforcements.

Vortex Shedding Fix

Spiral Strakes: Helical fins disrupt wind vortices, reducing oscillation by 40%.

Dampers: Tuned mass dampers absorb resonant vibrations.

3. Foundation Engineering: The Invisible Hero

Stability Trinity

| Foundation Type | Best For | Key Specs |

|---|---|---|

| Concrete Caisson | High-wind/soft soil | Depth: 15–20m; Diameter: 2–3m |

| Spread Footing | Rocky terrain | Width: 8m × 8m; Thickness: 3m |

| Pile Group | Swampy/marshy land | 12+ piles; Depth: 25–30m |

Anti-Overturning Math

F.S. = \frac{\text{Resisting Moment}}{\text{Overturning Moment}} \geq 2.5

Example Calculation:

-

Resisting Moment: Soil friction + foundation weight × lever arm

-

Overturning Moment: Wind force × tower height

4. Stress Distribution: Where Forces Hide (and How to Beat Them)

- Critical Weak Points

-

Base Flange: Bolt holes create stress concentrations (FEA reveals "hot spots").

-

Door Openings: Corners require rounded cutouts and reinforcement plates.

-

Antenna Mounts: Localized stresses demand gussets or collar stiffeners.

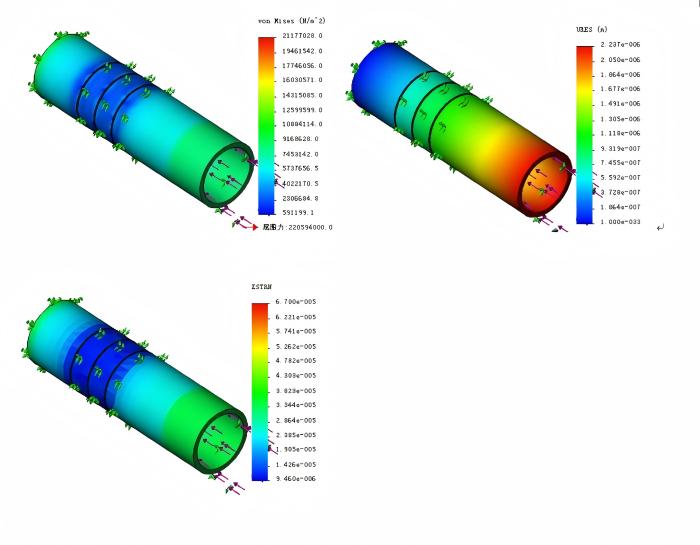

Finite Element Analysis (FEA) Snapshot

Red zones = High stress; Blue zones = Low stress

5. Extreme-Proofing: Case Studies

Typhoon Defense (Okinawa, Japan):

- Challenge: 70 m/s winds + salt corrosion.

- Solution: 35mm base thickness + sacrificial anodes + 120μm HDG coating.

Seismic Zone (San Francisco, USA):

- Challenge: Liquefaction risk during earthquakes.

- Solution: Floating slab foundation with rubber isolators.

Conclusion: Precision Over Power

Monopole towers exemplify "less is more" engineering—their strength emerges not from bulk, but from calculated geometry, smart material use, and ruthless simulation. As 5G densification and 6G terahertz bands demand lighter yet stronger towers, these principles will only grow more critical.

Engineered to Endure: At Altai Tower, we combine CFD/FEA-driven design with rigorous field testing to deliver monopoles that stand tall against nature’s fury. [Contact us] for a free structural resilience assessment!