-Introduction

The transition to 5G demands robust infrastructure capable of supporting higher frequencies, massive MIMO antennas, and multi-operator sharing. Among the various tower designs, 3-legged angle steel towers have emerged as a preferred choice for their exceptional strength, stability, and scalability. This blog delves into the technical design considerations that make these towers ideal for multi-operator 5G deployments, with a focus on load capacity, structural adaptability, and future-proofing.

1. Why 3-Legged Towers for 5G?

The triangular geometry of 3-legged towers provides innate stability and load-bearing efficiency. For 5G deployments, where antenna weight and wind load increase significantly, this design offers:

-

Superior Resistance to Overturning Moments: Triangular bases distribute mechanical stresses evenly.

-

Adaptability to Heavy Loads: Capable of supporting multiple operators’ equipment without structural compromise.

-

Ease of Installation and Maintenance: Modular designs simplify assembly and upgrades.

2. Key Technical Design Considerations

2.1 Load Capacity Analysis

5G deployments involve heavier antennas (e.g., massive MIMO units), more equipment, and higher wind loads. The tower must be designed to handle:

-

Dead Load: Weight of the tower itself, antennas, transmission lines, and platforms.

-

Live Load: Weight of maintenance personnel and tools.

-

Environmental Loads:

-

Wind Load: The largest variable. Calculated using standards like TIA-222-G or EN 1993-3-1, considering wind speed, antenna surface area, and tower height.

-

Ice Load: Critical in cold climates; ice accumulation on antennas and towers increases weight and wind drag.

-

--Example Load Calculation:

A 30-meter 3-legged tower in a coastal region (wind speed 50 m/s) with six 5G massive MIMO antennas per operator might need to support:

-

Antenna load: ~600 kg

-

Wind load: ~15 kN

-

Ice load: ~200 kg (if applicable)

2.2 Structural Design Specifications

-

Material Selection: High-strength steel (e.g., Q345 or ASTM A572) with a minimum yield strength of 345 MPa.

-

Corrosion Protection: Hot-dip galvanizing per ASTM A123 for longevity in harsh environments.

-

Connections: Bolted joints for ease of assembly and future modifications.

-

Foundation: Reinforced concrete foundations designed to resist uplift and overturning forces.

2.3 Multi-Operator Configuration

To host multiple operators, the tower must accommodate:

-

Antenna Mounting Positions: Multiple platforms at different heights to avoid interference.

-

Cable Management: Dedicated pathways for fiber and power lines to avoid clutter and ensure safety.

-

Weight Distribution: Asymmetric loading must be accounted for in the structural design.

3. 5G-Specific Design Challenges

-

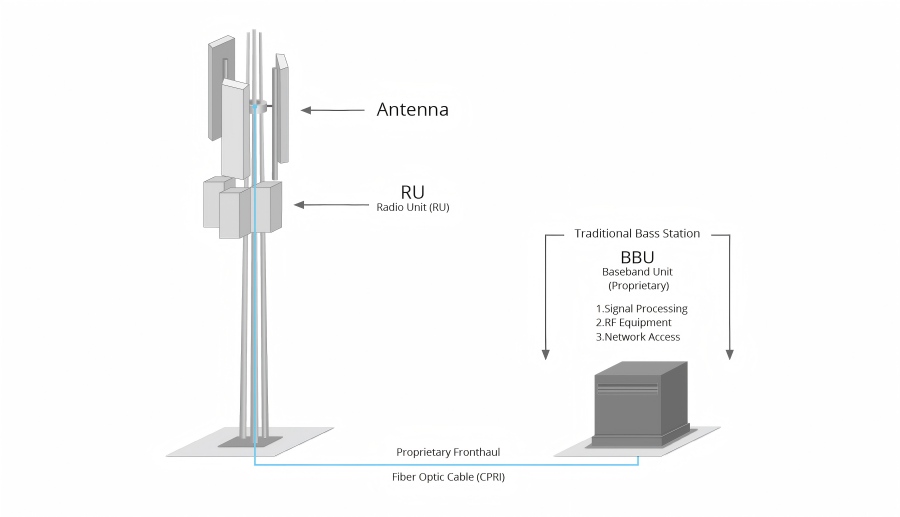

Massive MIMO Antennas: These are larger and heavier than previous generations. A single massive MIMO unit can weigh 20-30 kg, and towers may host dozens of them.

-

Wind Load Dynamics: The larger surface area of 5G antennas increases wind load, requiring stronger towers and foundations.

-

Frequency Interference: Antennas must be spaced to avoid interference, which influences tower height and platform design.

4. Case Study: Deploying a Multi-Operator 5G Tower

Project Overview: A 35-meter 3-legged tower in an urban area to host three mobile operators.

-

Load Requirements:

-

Each operator: six massive MIMO antennas, two microwave dishes, and remote radio units.

-

Total equipment weight: ~2,000 kg.

-

Wind load: 20 kN (based on local wind speed data).

-

-

Design Adaptations:

-

Additional bracing at higher elevations to handle asymmetric loads.

-

Custom platforms with dedicated mounting positions for each operator.

-

Foundation designed for 40-ton uplift capacity.

-

5. Standards and Compliance

-

International Standards:

-

TIA-222-G: Structural standards for antenna supporting structures.

-

EN 1993-3-1: European design standard for towers and masts.

-

-

Seismic and Cyclonic Standards: Region-specific codes (e.g., ISO 3010 for seismic design).

6. Future-Proofing the Design

-

Adaptability to 6G: Towers should be designed to accommodate even heavier and larger antennas.

-

IoT Integration: Support for sensors (e.g., structural health monitoring) to enable predictive maintenance.

-

Sustainability: Use of recycled steel and designs that minimize material usage without compromising strength.

Conclusion

The 3-legged angle steel tower is a technically sound solution for multi-operator 5G deployments. Its design efficiently balances load capacity, structural integrity, and adaptability, making it ideal for the demanding requirements of modern networks. By adhering to international standards and focusing on future-proofing, network operators can ensure their infrastructure remains viable for decades to come.

Learn more at www.alttower.com