Introduction

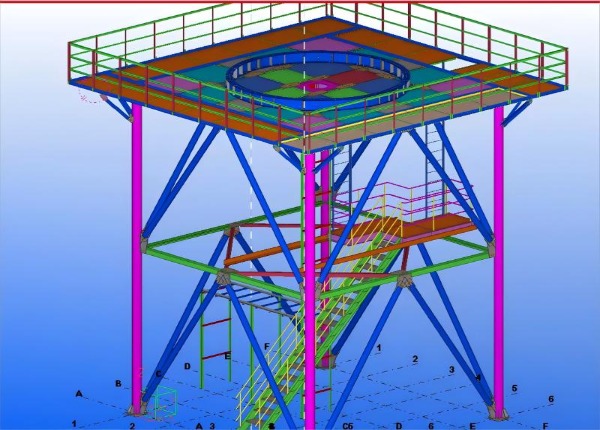

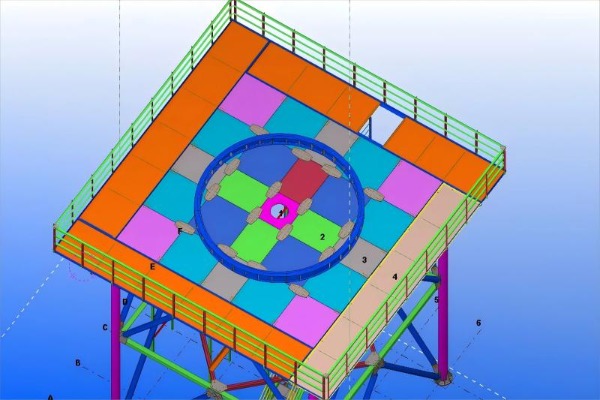

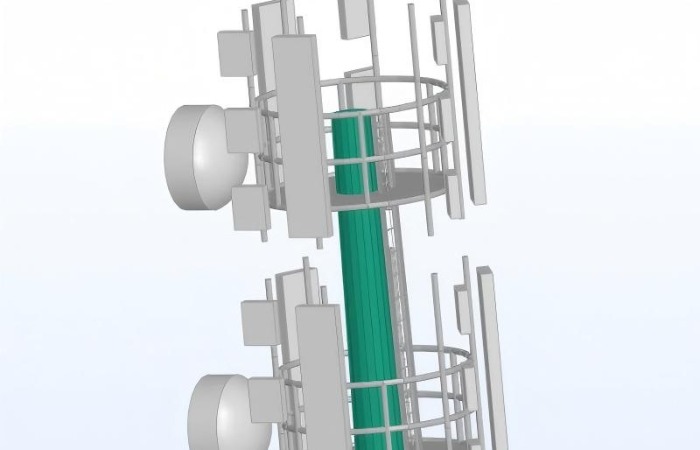

Critical infrastructure demands unparalleled reliability, and nowhere is this more crucial than for radar towers safeguarding aviation, maritime, and national security. These towers are strategically positioned in the most corrosive environments imaginable—exposed coastal zones where salt-laden air, high humidity, and intense UV radiation relentlessly attack structural steel. Ensuring their decades-long service life requires a deliberate, engineered approach to corrosion protection. This blog delves into the advanced defense strategies, centered on Hot-Dip Galvanizing (HDG) and specialized coating systems, that protect these vital assets.

1. The Unforgiving Enemy: Corrosion in Coastal Zones

The corrosion rate for steel in a marine environment can be 3 to 5 times faster than in a rural setting. The primary aggressors are:

-

· Salt Aerosols: Airborne chloride particles deposit on surfaces, forming a highly conductive electrolyte that accelerates electrochemical corrosion.

-

· High Humidity: Constant moisture facilitates the corrosion reaction, preventing protective films from forming.

-

· Cyclic Conditions: Daily temperature and humidity fluctuations cause "breathing," which can drive salt and moisture into micro-cracks.

-

· UV Degradation: Sunlight breaks down many organic polymer coatings, causing chalking, fading, and loss of film integrity.

For a radar tower, structural failure is not an option. The corrosion protection system must be designed from the outset for ultra-long-term performance with minimal maintenance.

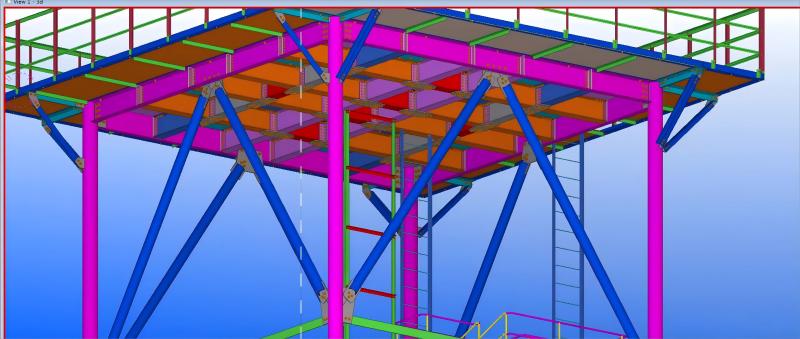

2. The First Line of Defense: Robust Hot-Dip Galvanizing (HDG)

Hot-dip galvanizing forms the foundational, metallurgically-bonded barrier for the entire steel structure. For coastal zones, standard HDG is not enough; an enhanced process is required.

-

· The Process: The fabricated steel is immersed in a bath of molten zinc at around 450°C (840°F). This creates a coating comprised of a series of zinc-iron alloy layers, topped by a layer of pure zinc.

-

· Enhanced Specifications for Coastal Use:

-

Increased Coating Thickness: We specify coatings that exceed standard requirements. For steel over 5mm thick, a minimum average thickness of 100-120 µm is targeted, in accordance with the most severe service categories of ISO 1461 (e.g., Category 4/5).

-

Superior Surface Preparation: To ensure perfect adhesion, steel undergoes rigorous cleaning (degreasing, pickling) and fluxing. The quality of this preparation directly dictates the quality and longevity of the zinc coating.

-

Controlled Withdrawal: The speed and angle at which the steel is withdrawn from the zinc bath are controlled to ensure a uniform, consistent coating, even on complex fabrications.

-

The HDG layer provides triple protection: a tough physical barrier, cathodic protection (where the zinc sacrificially corrodes to protect the underlying steel), and the unique ability to "heal" minor scratches through galvanic action.

3. The Secondary Shield: High-Performance Coating Systems

While HDG is exceptionally durable, adding a specialized coating system creates a synergistic "duplex system" that dramatically extends the service life of both the galvanizing and the coating.

-

· The Synergy of a Duplex System: The HDG layer prevents under-coating corrosion, which is the primary failure mode for paints. Simultaneously, the topcoat shields the zinc from direct exposure to the environment, significantly slowing its consumption rate. The combined system can offer 1.5 to 2.5 times the service life of either system alone.

-

· Coating Selection for Marine Atmospheres:

-

Epoxy Primers: These are chemically resistant and provide excellent adhesion to the galvanized surface, which must be lightly sweep-blasted or treated with a T-Wash (etching primer) to ensure proper bonding.

-

Polyurethane Topcoats: Chosen for their outstanding UV resistance, color and gloss retention, and superior weatherability. Aliphatic polyurethanes are the industry standard for a durable, flexible, and chemically resistant finish.

-

Advanced Resin Systems (e.g., Polysiloxanes): For the most demanding applications, polysiloxane hybrids offer even better UV and corrosion resistance than polyurethanes, with higher dry film thickness (DFT) application in a single coat and superior durability.

-

4. A Cohesive, Long-Life Protection Strategy

The effectiveness of this defense lies in the integration of all components:

-

· Design for Durability: The tower's design itself must avoid moisture traps, ensure good drainage, and provide adequate access for future inspection and maintenance.

-

· Rigorous Quality Control: Every step—from surface preparation and HDG bath chemistry to coating DFT verification (measured with magnetic gauges) and adhesion testing—is meticulously controlled and documented.

-

· Lifecycle Cost Advantage: While the initial investment in an HDG-plus-coating duplex system is higher, the dramatic reduction in maintenance, repainting, and risk of failure makes it the most cost-effective solution over the asset's entire lifecycle.

Conclusion

Protecting critical radar infrastructure in coastal zones is a battle fought with advanced materials science and precise engineering. By deploying a synergistic defense of thick, high-quality hot-dip galvanizing as a robust base, enhanced by a high-performance coating system tailored to withstand salt, sun, and moisture, we can ensure these vital towers stand guard reliably for decades. This multi-faceted approach to corrosion defense is not an expense; it is an essential investment in the resilience and security of our national critical infrastructure.

Learn more at www.alttower.com