Titanium—an extraordinary material hailed as the "space metal"—plays a crucial role in aerospace, medical implants, and high-end chemical industries due to its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. Seamless titanium tubes are the preferred choice for many demanding applications. But have you ever wondered how these flawless titanium tubes are manufactured? Let's step into the world of seamless titanium tube production.

I. Raw Material Processing

First, all incoming materials undergo inspection. After passing inspection, they are sawn and cut according to process requirements.

II. Forging of Raw Ingots

After heating the ingots, a high-speed forging mill is used to create the blank, followed by electro-hydraulic hammer forging of the raw ingot.

III. Blanking and Turning

The raw ingot is sawn and then machined into a finished bar conforming to process requirements using a lathe.

IV. Piercing

After heating the finished bar, it is pierced using a two-roll or three-roll skew rolling mill to produce a tube blank.

V. Sizing and Straightening

After piercing, the tube blank is sizing and straightened using residual heat to achieve the required dimensions.

VI. Surface Treatment

After piercing, the inner and outer surfaces of the tube blank need to be ground to remove defects.

VII. Cold Working

The tube blank undergoes rolling or drawing processes to produce finished tubes of the required dimensions.

VIII. Heat Treatment

Process standards are strictly followed, and the holding temperature, holding time, and cooling rate are precisely controlled. The temperature uniformity of the heating furnace is regularly tested. The inspector verifies that the heat treatment operation meets the process requirements and issues a heat treatment report.

IX. Straightening

Straightening is performed using a pipe-specific straightening machine. The curvature must meet the process requirements.

X. Surface Treatment

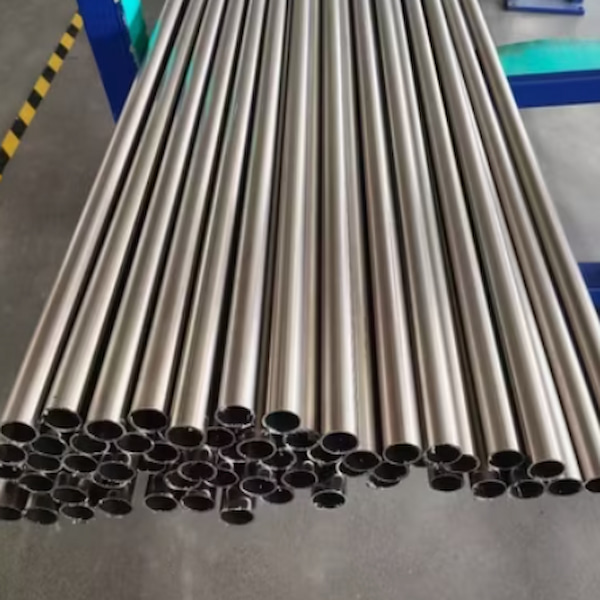

Polishing or pickling is performed according to the process standards. The inspector checks the surface quality and signs off upon acceptance.

XI. Cutting to Length

The finished pipes are cut to length according to the process requirements using a saw or pipe cutter, and the dimensions are verified.

XII. Warehousing

Before warehousing, the outer diameter, thickness, length, curvature, and other items of the pipes are inspected again. After the inspector confirms that all inspection items are qualified, the pipes are printed with codes, packaged, and put into storage.

Why Choose Seamless Titanium Tubes?

- Compared to welded titanium tubes, seamless tubes offer significant advantages:

- Seamless construction, uniform structure, and higher reliability

- Better pressure resistance and fatigue performance

- More uniform and isotropic mechanical properties

- Suitable for more demanding applications

From high-temperature smelting to precision cold working, every step embodies the essence of materials science and engineering. The next time you see fuel lines in aerospace engines, heat exchangers on deep-sea drilling platforms, or orthopedic implants in the human body, you'll know that behind these seamless titanium tubes lies an extraordinary journey from titanium ingots to precision tubing.

In the pursuit of lighter, stronger, and more durable materials, the manufacturing technology of seamless titanium tubes continues to evolve—with more precise dimensional control, superior performance customization, and more environmentally friendly production processes. This is the allure of materials engineering: transforming the elements of the earth into extraordinary products that drive human progress.