Introduction:

Angle steel communication towers are the backbone of modern telecommunication networks, supporting antennas, transmitters, and receivers that keep the world connected. However, these structures face relentless challenges—harsh weather, corrosive environments, and decades of service demands. The key to their longevity lies in a meticulously engineered combination of material science, advanced manufacturing, and proactive maintenance. In this blog, we unveil the technical strategies that ensure angle steel towers stand tall for generations.

1. Material Selection: The Foundation of Durability

The journey to durability begins with choosing the right steel. Not all steel is created equal:

High-Strength, Low-Alloy (HSLA) Steels: Grades like Q345B (China) or ASTM A572 (international) offer superior strength-to-weight ratios and resistance to atmospheric corrosion.

Environmental Adaptability: In coastal or industrial areas with high salinity or pollution, sulfur-resistant steels or aluminum-zinc alloy-coated materials may be prioritized.

Quality Standards: Compliance with ISO 1461 (hot-dip galvanizing) and ASTM A123 ensures material integrity from the outset.

Pro Tip: Over 70% of tower failures originate from substandard materials. Partnering with certified suppliers is non-negotiable.

2. Hot-Dip Galvanizing: The First Line of Defense

Hot-dip galvanizing (HDG) is the gold standard for protecting steel structures. Here's why:

Process: Steel components are immersed in molten zinc at 450°C, forming a metallurgical bond that creates a barrier against moisture and oxygen.

Benefits: A 100-μm HDG coating can provide 50+ years of protection in moderate environments, with self-healing properties to minor scratches.

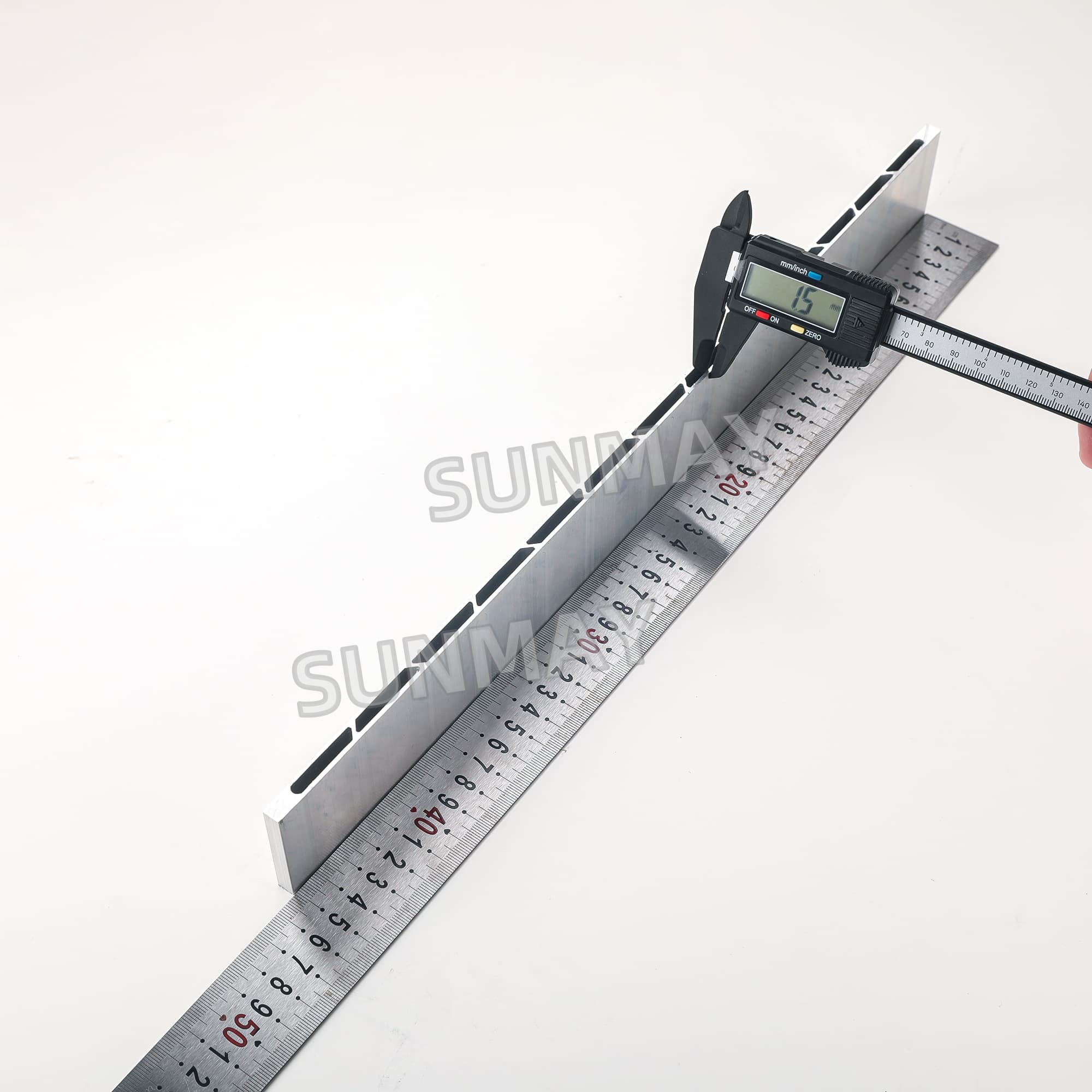

Quality Control: Coating thickness, adhesion, and uniformity are rigorously tested using magnetic gauges and cross-cut tests.

3. Advanced Coating Systems: Doubling Down on Protection

For extreme environments, supplementary coatings add an extra layer of security:

Epoxy Primers: Applied before galvanizing, they enhance adhesion and fill microscopic pores in the zinc layer.

Polyurethane Topcoats: UV-resistant finishes prevent chalkiness and fading in deserts or tropical climates.

Cathodic Protection: For towers in coastal zones, sacrificial anodes (e.g., zinc or magnesium) are installed to divert corrosion away from critical joints.

Case Study: A tower in Saudi Arabia's Rub' al Khali desert survived 15 years of sandstorms and 50°C heat using a hybrid HDG-polyurethane system.

4. Maintenance Strategies: Prolonging Tower Lifespan

- Even the best materials need vigilant upkeep:

-

Biannual Inspections: Use drones and ultrasonic sensors to detect cracks, coating degradation, or rust spots.

-

Cleaning Protocols: Remove salt deposits, bird droppings, and debris that trap moisture.

-

Touch-Up Kits: Rapid-repair solutions for damaged coatings, such as zinc-rich paints or cold galvanizing compounds.

- 5. The Future: Smart Corrosion Monitoring

- IoT-enabled sensors are revolutionizing tower maintenance:

-

Real-Time Data: Embedded sensors track corrosion rates, strain, and environmental factors (humidity, pH).

-

Predictive Analytics: AI algorithms forecast maintenance needs, slashing downtime by up to 40%.

- Conclusion

The durability of angle steel communication towers isn't accidental—it's the result of science, precision engineering, and relentless innovation. By prioritizing high-quality materials, multi-layered anti-corrosion systems, and smart maintenance, operators can ensure these critical infrastructures withstand the test of time and nature.

Learn more at www.alttower.com