As telecommunication providers race to expand network coverage—whether for 4G, 5G, or future technologies—the choice of infrastructure plays a critical role in determining the speed, cost, and long-term viability of large-scale rollouts. Among the available options, 3-legged lattice towers stand out as a proven, cost-effective solution for bridging vast urban and rural areas. This blog explores the structural, logistical, and economic factors that make these towers ideal for massive network deployments.

1. The Challenge of Large-Scale Network Rollouts

Deploying thousands of towers across diverse terrains requires balancing three key constraints:

-

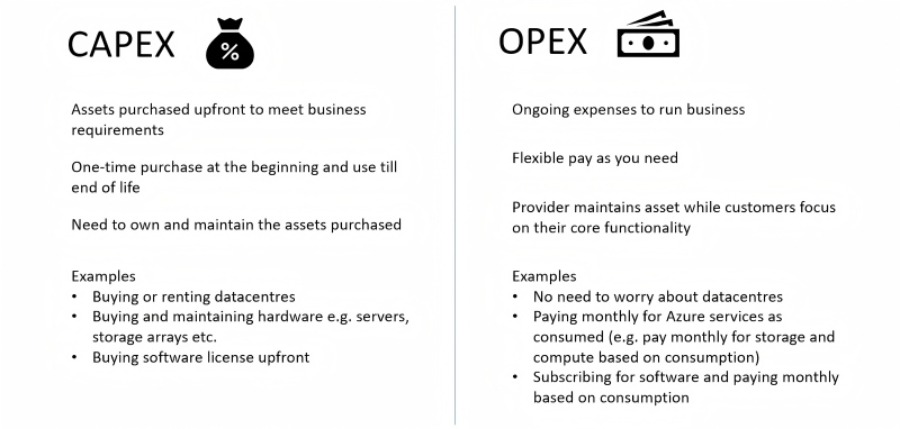

Capital Expenditure (CAPEX): High upfront costs for materials, transportation, and installation.

-

Operational Expenditure (OPEX): Ongoing maintenance, energy consumption, and site management.

-

Scalability: The ability to rapidly scale infrastructure without compromising reliability.

Traditional monopoles or tubular structures often struggle to meet these demands in rural or rugged environments, where load requirements, wind resistance, and multi-operator hosting capacity are critical.

2. Structural Efficiency: The Foundation of Cost Savings

The triangular geometry of 3-legged lattice towers provides inherent advantages that directly reduce costs:

-

Material Optimization:

-

-Lattice designs use 30–40% less steel than solid-walled monopoles of equivalent height and load capacity.

-

-The open-frame structure minimizes weight while maintaining strength, reducing material and fabrication expenses.

-

-

Load Distribution:

-

-The triple-leg configuration evenly distributes mechanical stresses (wind, ice, equipment weight), allowing taller heights (up to 80+ meters) without proportional cost increases.

-

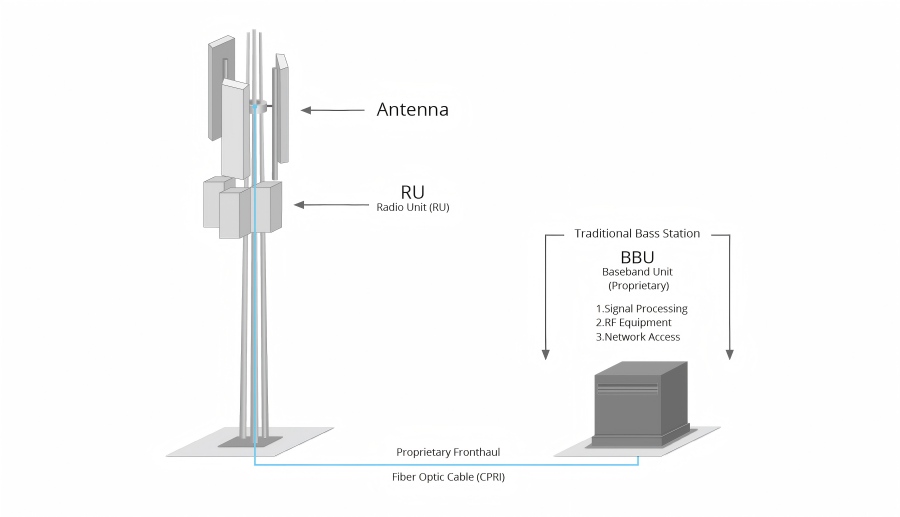

-This design supports heavier multi-operator loads—critical for hosting 5G massive MIMO antennas and microwave backhaul equipment.

-

3. Logistical Advantages: Simplifying Deployment

Large-scale rollouts require streamlined logistics. 3-legged lattice towers excel in:

-

Modular Fabrication:

-

-Components are pre-assembled in standardized sections for rapid on-site bolting, cutting labor time by up to 50% compared to welded alternatives.

-

-Modularity allows for transport in compact batches, easing delivery to remote or congested areas.

-

-

Adaptability to Terrain:

-

-The triangular base can be anchored to varied foundations (concrete, rock, or soil), avoiding costly customizations for uneven ground.

-

-Lightweight segments enable installation with smaller cranes, reducing equipment rentals.

-

4. Lifecycle Cost Analysis: CAPEX vs. OPEX

While lattice towers may have marginally higher initial fabrication costs than simple poles, their total cost of ownership (TCO) is often lower over decades of service:

| Cost Factor | 3-Legged Lattice Tower vs. Monopole/Tubular Tower |

|---|---|

| Initial Material Cost | Comparable or 5–10% higher due to complex fabrication. |

| Transportation | 20–30% lower due to modular, lightweight components. |

| Installation Time | 30% faster for tall towers (bolted connections). |

| Maintenance | Minimal; hot-dip galvanizing provides 40+ years of corrosion resistance. |

| Capacity Expansion | Easy bolt-on upgrades for new antennas; no structural reinforcement needed. |

Case studies from wind farm projects—where lattice towers save 34% in steel consumption—demonstrate similar scalability benefits for telecom deployments.

5. Real-World Applications: Evidence from the Field

-

-Rural Telecom Projects: In regions like Southeast Asia and Africa, lattice towers host multiple operators simultaneously, sharing infrastructure costs while delivering coverage to underserved communities.

-

-Disaster Resilience: Their robust design withstands extreme weather (cyclones, earthquakes), reducing downtime and repair costs.

-

-Sustainable Design: Less material usage translates to lower carbon footprints, aligning with ESG goals for green network expansion.

6. Future-Proofing Networks

The flexibility of lattice towers makes them adaptable to evolving technologies:

-

-5G/6G Readiness: Support for heavy antenna arrays and fiber-optic cabling along the tower’s frame.

-

-IoT Integration: Mounting points for sensors, solar panels, or edge computing modules.

-

-Cost Predictability: Standardized designs and suppliers ensure budget control for multi-year rollouts.

7. Conclusion: The Smart Choice for Scalability

For large-scale network rollouts, 3-legged lattice towers offer an unmatched blend of durability, scalability, and cost efficiency. By optimizing material use, accelerating deployment, and minimizing lifecycle expenses, they enable providers to connect more people—faster and more affordably—than alternative structures. As digital connectivity becomes a global priority, this timeless engineering solution continues to prove its value in building the networks of tomorrow.

Learn more at www.alttower.com