In modern construction, long service life, durability, and low maintenance costs are among the top priorities for building owners and contractors. Surface treatment methods that meet these requirements include painting and hot-dip galvanizing. Both processes provide excellent corrosion resistance, extend the lifespan of structures, and reduce maintenance expenses.

What is hot-dip galvanized steel structure?

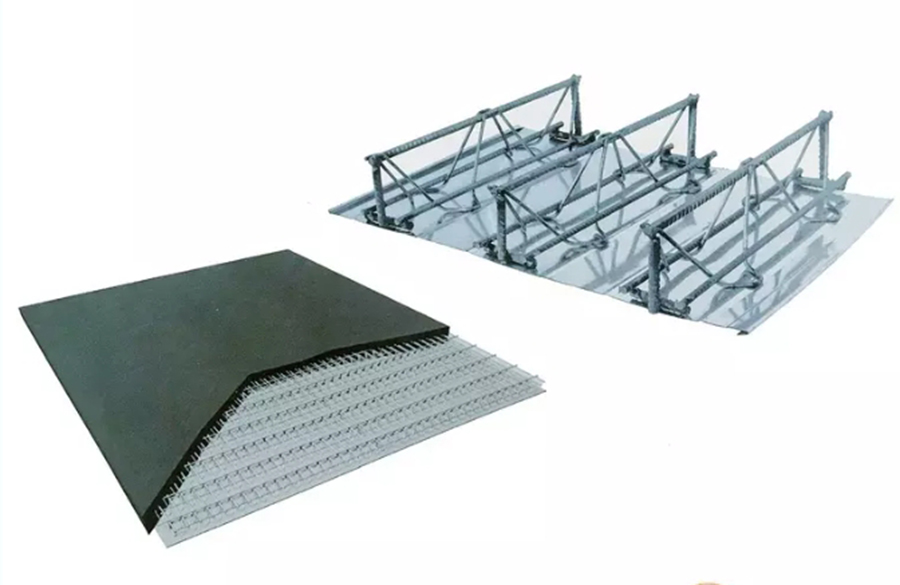

A hot-dip galvanized steel structure is a corrosion-resistant framework produced by immersing fabricated steel components into molten zinc heated to approximately 450°C (840°F). Through this metallurgical process, the zinc reacts with the steel to form a series of tightly bonded zinc-iron alloy layers, topped with pure zinc. The resulting coating provides durable, long-term protection that significantly extends the service life of the structure.

What is painted steel structure?

Painted steel structure is a steel construction, such as a building frame or bridge, that has been coated with paint to protect it from corrosion and enhance its appearance. The painting process involves applying primer, an intermediate coat, and a topcoat, using methods like brush, roller, or spray application. Common paint types for steel include epoxy, polyurethane, acrylic, and alkyd paints, chosen based on durability requirements and the environment.

What is the difference of the hot-dip galvanized and painted steel sturcure?

☆ Treatment Processes

|

Hot-Dip Galvanizing Processing Steps |

Painting Processing Steps |

|

1. Cutting and Punching |

1. Cutting and Punching |

|

2. Assembly and Welding |

2. Assembly and Welding |

|

3.Degreasing → Pickling → Fluxing → Drying |

3. Shot Blasting (Generally Default: Level 2.5) |

|

4.Hot-Dip Galvanizing (According to Required Coating Thickness) |

4.Spray Painting (Based on Thickness and Coating Requirements) |

☆Forms

Hot-dip galvanizing provides superior, sacrificial zinc protection that chemically bonds with steel for long-term, low-maintenance, and scratch-resistant corrosion resistance.

Painting is a surface-level barrier coating that offers only limited protection, is more prone to chipping and scratching, and requires regular maintenance to maintain its integrity.

While paint provides a wider range of aesthetic color options and is a cheaper initial option, hot-dip galvanizing is more durable, has a longer service life, and offers better protection, especially in harsh environments.

☆Protection Type

Hot-dip galvanizing creates a metallurgical bond with the steel, offering both barrier and sacrificial protection.

Painting is a simple barrier coating that adheres to the steel's surface.

☆Durability & Maintenance

Hot-dip galvanizing is exceptionally durable, scratch-resistant, and requires minimal maintenance, as the zinc coating forms part of the steel itself.

Painting is less durable and more prone to chipping, scratching, and fading, leading to exposed steel and subsequent rust.

☆Service Life

Hot-dip galvanizing offers extended service life, often providing maintenance-free protection for 75 years or more in many environments.

Painting,the protective paint layer wears down and may need recoating every 3-7 years, depending on the environment and paint quality.

☆Corrosion Resistance

Hot-dip galvanizing provides outstanding corrosion resistance due to the zinc's ability to act as a sacrificial layer.

Painting protects against rust only as long as the coating remains intact.

☆Aesthetics

Hot-dip galvanizing has a bright gray hue, offering limited aesthetic customization.

Painting offers a wide variety of color choices to match project requirements.

☆Cost

Hot-dip galvanizing is higher initial cost than paint, but lower lifecycle costs due to reduced maintenance requirements.

Painting ,a lower initial cost for the paint and its application, making it a cheaper upfront option.

In conclusion, hot-dip galvanized and painted steel structures differ significantly in corrosion resistance, maintenance needs, lifespan, and cost. The optimal choice depends on specific project requirements, environmental conditions, and long-term performance expectations. Each method offers distinct advantages tailored to different applications.

If you have any questions,please contact the Yumisteel team for tailored solutions!Thank you!

It is very important to understand the differences between

It is very important to understand the differences between