The rollout of 5G technology promises unprecedented speed, low latency, and massive connectivity. However, achieving these goals in densely populated urban areas presents a significant challenge: space constraints. Traditional lattice towers and macro sites are often impractical due to their large footprint, aesthetic intrusion, and zoning restrictions. Enter the monopole tower—a sleek, space-efficient solution that is driving 5G densification in cities worldwide. This blog explores how monopoles are addressing urban infrastructure challenges and enabling the next generation of wireless networks.

1. The Challenge: 5G Densification in Urban Areas

5G networks rely on densification—deploying more small cells and antennas per square kilometer—to deliver high capacity and coverage. Unlike 4G, which used larger cells spaced farther apart, 5G requires smaller cells placed closer together, especially in urban environments. Key challenges include:

-

Limited Physical Space: Rooftops, streets, and public areas are already crowded with existing infrastructure.

-

Aesthetic Concerns: Communities often resist unsightly towers that disrupt cityscapes.

-

Zoning Regulations: Municipalities impose strict guidelines on tower height, appearance, and placement.

2. Why Monopoles? The Space-Saving Advantage

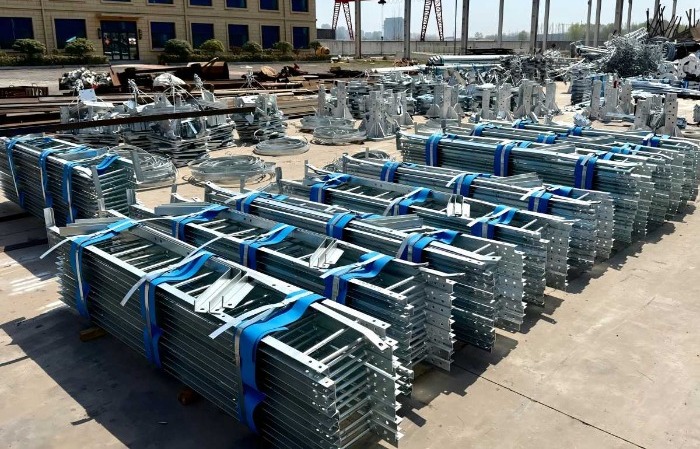

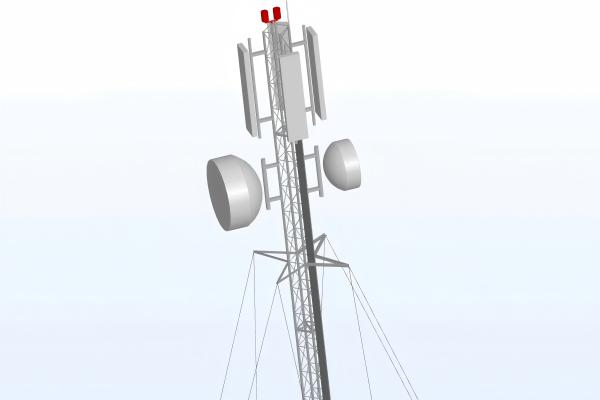

Monopoles are single, slender poles made of steel or concrete, typically ranging from 10 to 40 meters in height. Their design offers several critical advantages for urban deployments:

-

Small Footprint: Monopoles require minimal ground space, often as little as 1–2 square meters, making them ideal for sidewalks, medians, and building rooftops.

-

Stealth Design: They can be camouflaged as streetlights, flagpoles, or architectural features, addressing aesthetic concerns and easing regulatory approval.

-

Rapid Deployment: Prefabricated components and modular designs reduce installation time, minimizing disruption in busy urban areas.

-

Multi-Functionality: Monopoles can host 5G antennas, small cells, IoT sensors, and public lighting, consolidating infrastructure and reducing clutter.

3. Technical Innovations Driving Urban Adoption

Monopoles are evolving to meet the specific demands of 5G densification:

-

Structural Adaptability: Engineers design monopoles to support the weight and wind load of multiple antennas and equipment, often using high-strength steel or composite materials.

-

RF Optimization: Their height and placement are optimized for line-of-sight propagation, reducing signal interference and improving network performance.

-

Power and Fiber Integration: Monopoles can incorporate concealed conduit for fiber backhaul and power lines, simplifying connectivity.

4. Real-World Applications and Case Studies

-

Smart Streetlights: Cities like Los Angeles and Singapore deploy monopoles disguised as streetlights, hosting 5G small cells and sensors for traffic management and public safety.

-

Rooftop Deployments: In dense areas like Hong Kong, monopoles on rooftops provide coverage without occupying valuable ground space.

-

Transportation Hubs: Monopoles at airports and train stations (e.g., London’s Canary Wharf) deliver high-capacity connectivity to large crowds.

5. Overcoming Urban Deployment Barriers

Monopoles help operators navigate common urban challenges:

-

Community Acceptance: Stealth designs blend into the environment, reducing NIMBY (“Not In My Backyard”) opposition.

-

Regulatory Compliance: Manufacturers work with cities to ensure designs meet zoning height and aesthetic requirements.

-

Cost Efficiency: While installation costs vary, monopoles’ modularity and shared infrastructure (e.g., hosting multiple carriers) lower long-term expenses.

6. The Future: Monopoles and Beyond

As cities advance toward 6G and smart city ecosystems, monopoles will play an even greater role:

-

AI-Driven Maintenance: Sensors on monopoles can monitor structural health and optimize network performance in real time.

-

Sustainability Integration: Solar panels and energy-efficient designs will reduce the carbon footprint of urban networks.

-

Edge Computing: Monopoles may house edge servers to process data locally, enabling ultra-low-latency applications.

Conclusion: The Urban Connectivity Backbone

Monopole towers are the unsung heroes of urban 5G densification, offering a pragmatic solution to space constraints while enabling the high-performance networks of tomorrow. Their versatility, stealth capabilities, and technical adaptability make them indispensable for building connected, smart, and sustainable cities. As demand for bandwidth grows, monopoles will continue to evolve, ensuring that urban areas remain at the forefront of the digital revolution.

Learn more at www.alttower.com